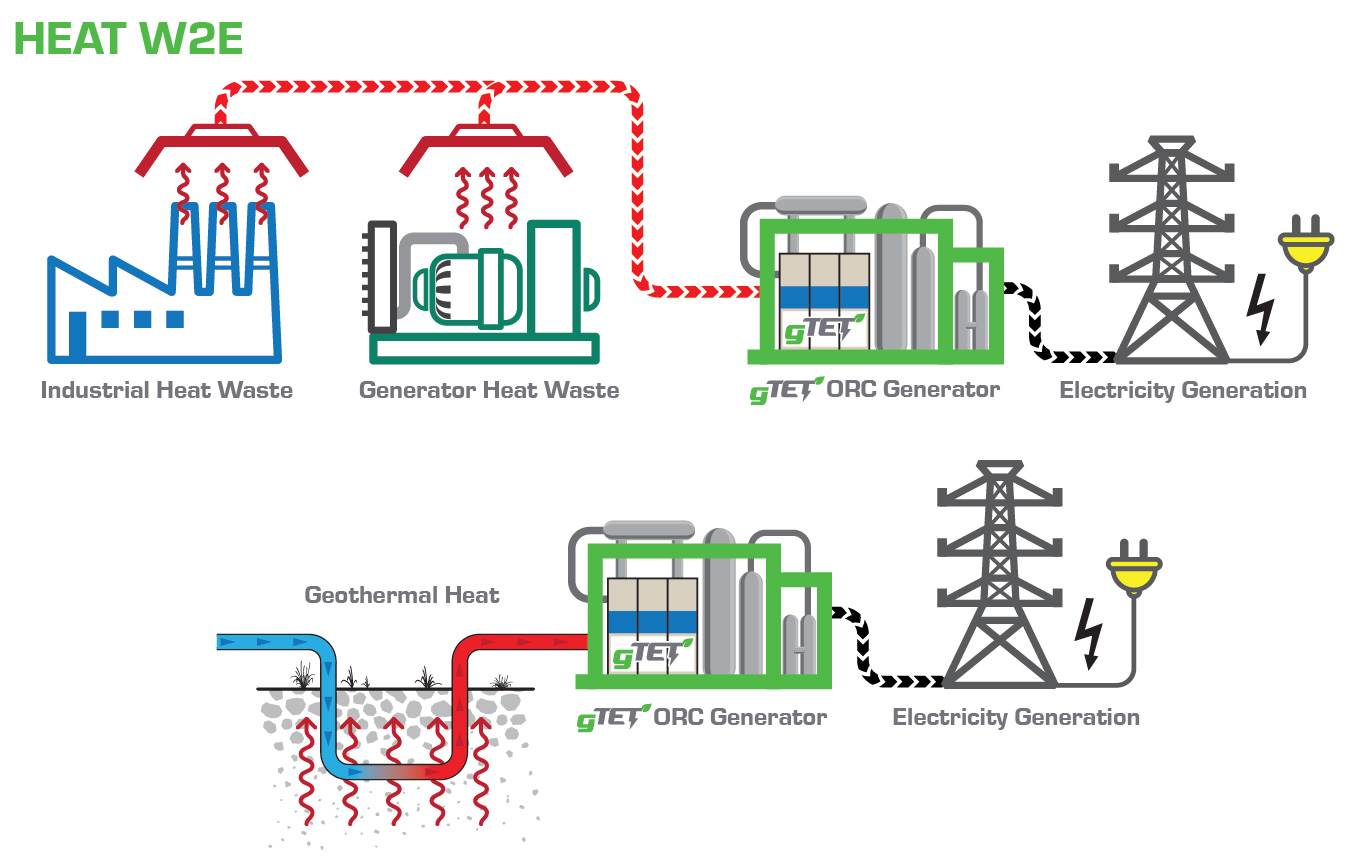

Heat Waste to Energy (W2E)

- The heat is transferred to the power generation system via a suitable fluid including steam, pressure hot water, glycol, thermal oil etc

- The heat is used for power generation using gTET’s revolutionary Organic Rankine Cycle (ORC) generator.

- Heat that can be demonstrably renewable based such as geothermal or solar thermal result in the power station being classified as ‘renewable power’

- If the site also requires heat e.g drying, the power station can also be configured as Combined Heat & Power (CHP) delivering low grade heat for other processes.

- The power stations are typically designed for minimal operating expense (OPEX) by avoiding regulated conditions such as full time manned high pressure steam turbine plants.

Case Studies

Heat W2E Case Study: Capstone Gas Turbine

Location:

Industry:

Source:

Thermal Process:

Power Generation

Economics:

Optimal

Power Generation

Capstone C1000 Exhaust

Gas turbine exhaust to exhaust to water heat exchanger then transferred to the ORC generator.

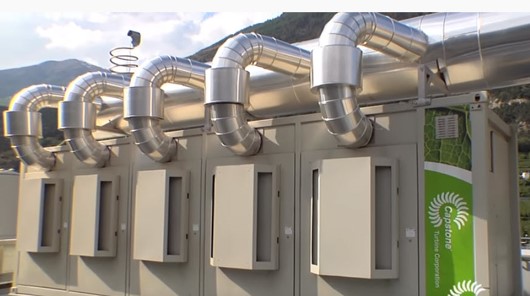

170kWe gTET ORC Generator with adiabatic cooling. None export power

Power generation estimates at $100kpa

Heat W2E Case Study: Koppers Minerals

Location:

Industry:

Source:

Thermal Process:

Power Generation

Economics:

Newcastle, NSW, Australia

Minerals

Industrial Exhaust Flue Gas

Exhaust gas to thermal oil heat exchange then transferred to the ORC generator.

170kWe gTET ORC Generator with water cooling. None export power

Power savings estimates at $50kpa

Heat W2E Case Study: Winton Geothermal

Location:

Industry:

Source:

Thermal Process:

Power Generation

Economics:

Winton, Queensland, Australia

Government

Geothermal-town water supply

86°C water from the Artesian Basin

2x 150kWe gTET ORC Generator with water cooling. Primarily export power

Power generation/ savings around $50k-$75k pa (depending upon water consumption) plus renewable energy credits.