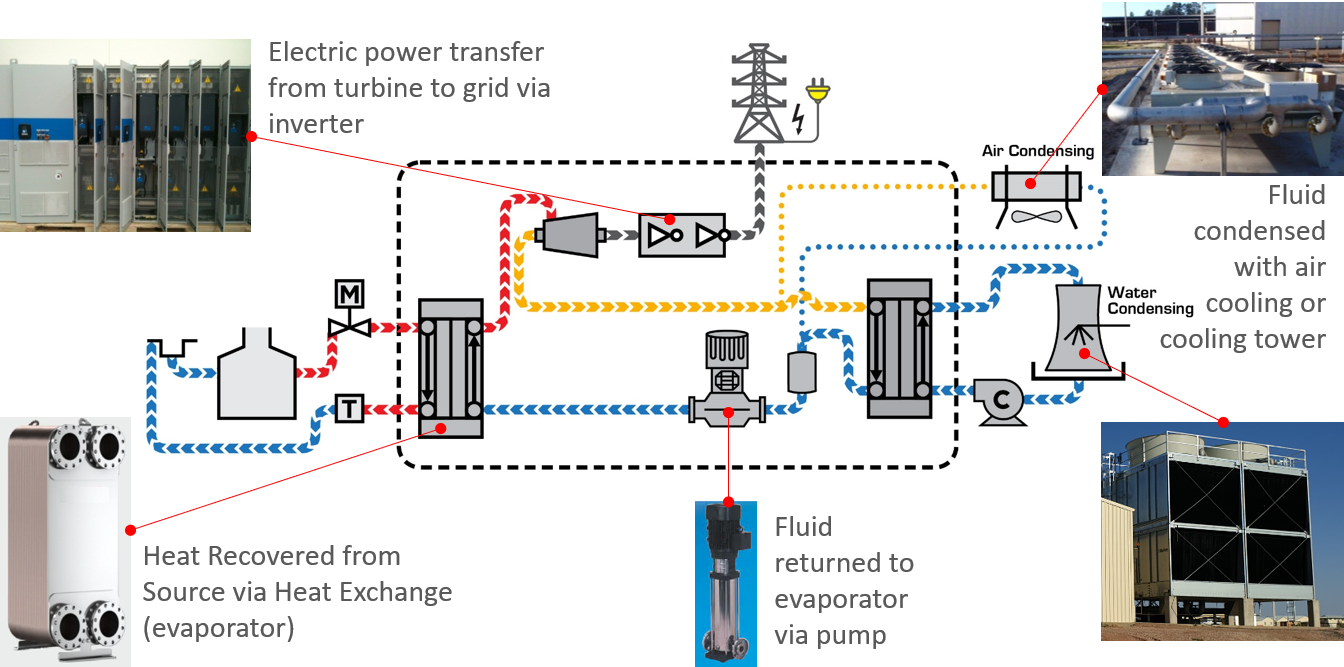

Organic Rankine Cycle (ORC) Generator

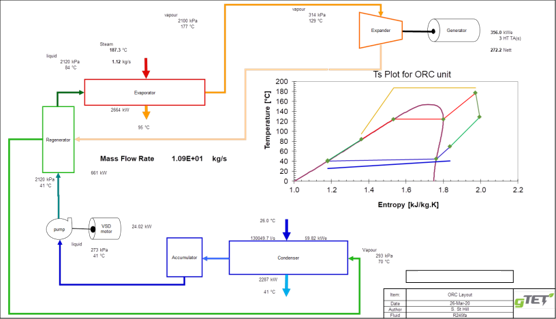

A closed loop thermodynamic cycle using an organic fluid selected to develop sufficient pressure to efficiently operate a turbine at the source temperature.

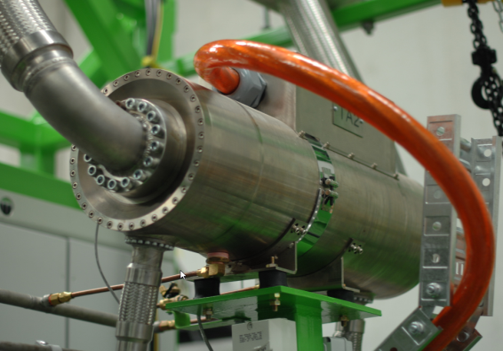

Revolutionary Turbo-alternators:

- High speed, 45,000rpm; minimises the size

- Gas foil bearing technology; long life with high reliability and oilless system. No bearing ancillary equipment

- Integrated hermetically sealed turbine and alternator; eliminates potential for rotating shaft seal leaks and improved efficiency

- Stator and bearing cooling using the working fluid; no ancillary cooling.

- High Frequency AC alternator; single shaft with turbines eliminates coupling inefficiencies

- Unique twin turbine minimises thrust bearing loads

- High temp (170kW) & Low Temp (60kW) available

High Speed Electronic Drive (AS4777 & IEC62109 certified) :

- Customised to gTET’s HFAC Turbo-Alternator, 750Hz.

- Turbine control non-synchronous and independent to grid.

- Manages regulatory requirements for grid connection

- Provides variable speed drive for ORC pump and cooling tower pump and fan

- Electrical load is customised in software to match the turbo-alternator performance for maximum efficiency while protecting the turbine.

- System turn-down by 90% to match fluctuating heat source

Experienced & Capable Engineering :

System modelling tools:

- Accurate system modelling correlated with numerous applications

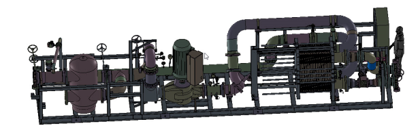

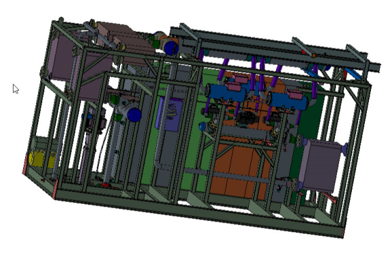

Computer based Design Tools:

- Latest CAD and CAE tools used to enable designs to be completed and verified in the virtual environment prior to fabrication and factory testing

Experienced Team:

- Design and deliver team experienced and certified in thermodynamics, mechanical and electrical design.

- Experienced program management and site installation team.

- Licenced building practitioners in Queensland Australia.